What Are the Major Wax Markets?

Major Wax Markets and trends in USA Wax Production and Imports

In North America the consumption of wax is approximately 3 billion pounds per year. Packaging represents about 30% of the market; while this importance of waxed paper, milk cartons, paper drinking cups, etc., has declined, other new applications for waxes have increased the overall consumption level. The biggest single consumer of wax in North America remains the packaging; the next biggest (and fastest growing) segment is candles, followed by building materials, firelogs, and industrial liquids and emulsions of many kinds.

Building Materials: wax is added as a water repellent in the production of wood-based manufactured composite boards such as particle board, medium density, oriented strand and other board products.

Candles: one of the oldest uses of wax, but still vital. No longer used for primary illumination, candles are the fastest growing segment of the wax market with new decorative and therapeutic uses.

Chlorinated paraffins: chemicals manufactured by chlorination of paraffin waxes. The largest application for chlorinated paraffins is as a plasticiser and flame-retardant in flexible PVC. They are also used as plasticisers in paint, sealants and adhesives. The higher chlorine content grades are used as flame-retardants in a wide range of rubber and polymer systems. Another major outlet for chlorinated paraffins is in the formulation of metalworking lubricants where they have long been recognized as one of the most effective additives for lubricants used in a wide range of machining and engineering operations. Finally, they are used in leather formulations.

Corrugated Board: wax is applied to corrugated containers in order to provide wet and top to bottom strength, key concerns in food packaging.

Coatings: wax can be used to form a coating that allows oxygen to pass but not water; generating numerous applications in such diverse areas as cosmetics, food, packaging, furniture, time release properties, etc.

Coatings: wax can be used to form a coating that allows oxygen to pass but not water; generating numerous applications in such diverse areas as cosmetics, food, packaging, furniture, time release properties, etc.

Cosmetics: fully-refined wax is non-toxic, and many products are approved by the FDA for direct use in food and personal care formulations. Waxes are widely used in the cosmetic industry in products such as lipstick, mascara, moisturizing creams and sunblocks.

Chewing gum: chewing gum base is a compound of elastomers, resin and FDA wax to which other materials are added to produce chewing gum. Hard, high melt-point waxes are used in this application, including microcrystalline and candelilla waxes.

Crayons:FDA wax provides the solid structure for a crayon and, since most crayon users are young children, its non-toxic characteristics are critical.

Firelogs: a modern convenience product, wax acts as both a binder and as fuel.

Food: FDA wax is used to cover certain types of cheese that would dehydrate if not properly protected, is sprayed on citrus and other fruit to protect from oxidation and enhance appearance, and in meat/bone wraps.

Hot melt adhesives: waxes are present in most hot melt adhesive formulations, where they control the viscosity of the adhesive and contribute to open time, flexibility and elongation.

Inks: graphical printing inks include wax in their formulation to make them brighter and to improve sliding capabilities, as well as to prevent scratches that affect some printing inks.

Investment casting: in the "lost wax" method of casting of jewelry, industrial products, etc. a wax model of the piece is made, then used to create a clay mold. The wax is melted out, and the clay used to cast the final piece.

Polishes: the application of waxes to wooden floors to improve their appearance and provide protection dates back several hundred years. The application of wax retards the penetration of air and moisture, thereby increasing the life of the flooring material as well as preventing abrasion by surface grit.

PVC: two different lubricants are used in the manufacture of polyvinyl chloride thermoplastic: internal and external. Two different types of wax are used in the lubricants. Internal lubricants are formulated to help PVC flow in the manufacturing process; they form a solution with PVC. External lubricants are not soluble in PVC and they produce a film between the PVC and its extrusion equipment.

Tire and Rubber: wax is a vital component in rubber tire formulations; it is added for protection from atmospheric ozone that will "dry" unprotected rubber, causing cracking that compromises the strength of the tire. Wax creates a physical barrier between the tire surface and the atmosphere.

Wax Production and Imports

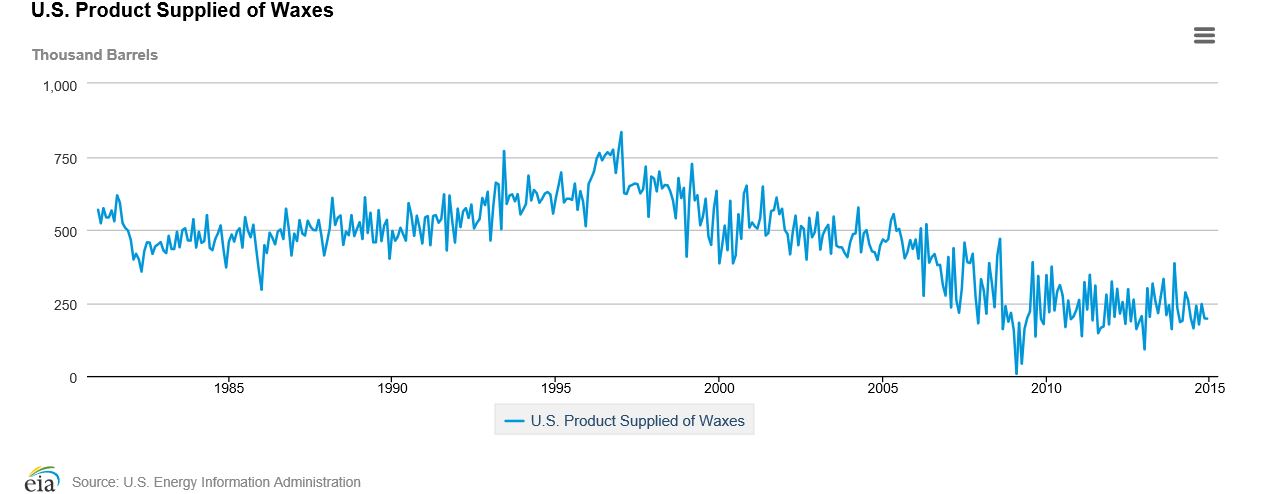

U.S domestic wax production has fallen steadily from its peak in 1998.

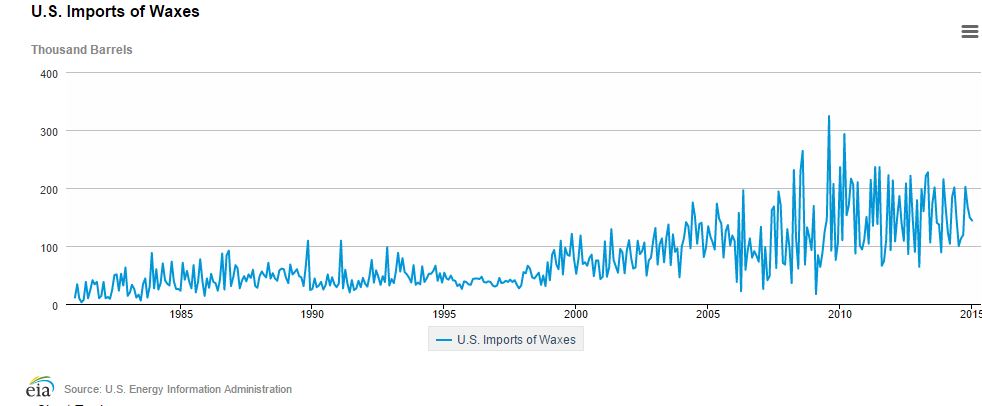

Wax imports in the USA have, meanwhile, increased.

IRM has relationships with the major sources of these imports, and our customers benefit from the added, reliable supply channels that we can provide.

IRM has relationships with the major sources of these imports, and our customers benefit from the added, reliable supply channels that we can provide.